Optimizing Yield and Potting Practices

By Pierre-Marc de Champlain, Director – Technical Services

Berger adjusts the chemical and physical characteristics of its growing media to match grower needs. However, it is the grower’s responsibility to manage the structure of the growing media in the containers. Proper handling before, during and after potting is critical for optimizing the root environment.

Advice no1

Storage

Bags or bales should be stored in a cool area out of direct sunlight as much as possible. If the material is stored for long periods (> 4 months), the wettability of the growing media should be verified before use.

Advice no2

Growing Media Handling

When handling, the goal is to prevent damage to the growing media as much as possible. Fluffing and potting equipment should be selected and adjusted with care.

Advice no3

Avoid Compaction

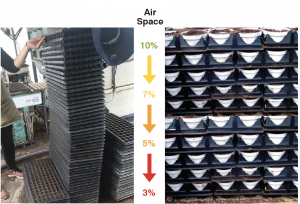

Growers should avoid compacting their growing media at all costs. Compaction reduces air space and increases water retention. Each action affects the physical structure of the growing media in its containers. The height of the brush needs to be properly adjusted for each type of container. Excessive vibrations on the conveyor can compact the growing media in the container. An automatic dibbler can significantly compress the growing media if it isn’t adjusted properly. The height from which the growing media falls into the container has a direct impact on porosity.

| Action | Compaction | Air Space* |

| Fill & Brush | Light | 18% |

| Double-tap (or ex-cessive vibration) | Medium | 13% |

| Hard pack (or high drop into container) | Heavy | 10% |

*Approximate values.

Nesting stacks of pre-filled containers and trays will increase compaction and create inconsistencies.

This can be avoided by offsetting trays or using rigid sheets between rows of containers.

Advice no4

Adjusting the Water Content

Berger sells growing media, not water. We keep the water content of our mixes as low as possible to maximize the number of skids per truckload.

An additional 5% in water content represents roughly 2000 lbs. on a full truckload, which is approximately the weight of one full skid.

Berger has the smallest water content range in the industry: approximately ½ gallon per cubic foot of growing media. This makes it easier to adjust the water content prior to potting. Most Berger products have an initial water content of 43 to 46%, while the water content of our competitors’ products can be as low as 35% and as high as 75%.

There are many advantages to adjusting the water content before potting:

-

Increased Yield

High-quality sphagnum peat moss swells when rehydrated to its optimum water content for potting (55–65%). This can increase yield by up to 15%.

-

Reduced Dust

The finer particles tend to cluster together and form aggregates when water is added.

-

Increased Porosity

Both the expanded peat fibers and the aggregates help optimize soil structure and maximize porosity in containers.

-

Improved Water Distribution

Higher water content reduces the surface tension and improves the wettability of the substrate. This helps reduce channeling.